The Ultimate Guide to Commercial Refrigeration Maintenance for RestaurantsNathalie Schrans

Nathalie Schrans

Nathalie Schrans

- 1. Stay on Top of Regular Preventative Maintenance (PM)

- 2. Train Staff to Perform Basic Checks and Regular Cleaning

- 3. Avoid Overloading and Poor Placement

- 4. Prioritize Critical Equipment

- 5. Proactively Manage Warranty and Repair Costs

- 6. Build a Reliable Vendor Network

- 7. Plan for Critical Failures

- 8. Use Software for Maintenance Tracking

- Simplify Commercial Refrigeration Maintenance with OpenWrench

In This Post

A refrigeration failure in a busy restaurant can derail operations, spoil inventory, and rack up costly repairs. For facilities managers overseeing multiple locations, keeping systems in top condition is critical — but where do you start?

We spoke with Danny Koontz of Windy City Equipment, a seasoned expert with decades of experience in restaurant facilities management and equipment repair, to get his top tips on commercial refrigeration maintenance. These best practices will help you extend equipment lifespans, prevent breakdowns, and save time.

After reading our guide, you’ll learn how to:

- Prevent equipment failures and reduce downtime with preventative maintenance schedules

- Train staff to perform basic checks can catch issues before they escalate

- Avoid common mistakes like overloading and poor placement

- Use tools like facilities management software to simplify maintenance tracking and vendor coordination

1. Stay on Top of Regular Preventative Maintenance (PM)

Without consistent preventative maintenance (PM), small problems like a dirty coil or a torn gasket can grow into major failures.

“Do your PM quarterly if you can,” says Danny. “Many people will skip PM as a cost-cutting measure. But you need at least two or three visits per year.”

During PM visits, a service technician should:

- Check for leaks

- Inspect and replace worn gaskets

- Check door seals

- Inspect and adjust door hinges

- Clean condenser and evaporator coils

- Check and replace air filters

- Inspect fan motors

- Inspect and tighten electrical connections

- Test and calibrate thermostats

- Check that temperatures are consistent

- Test door heaters for walk-in units

- Check refrigerant levels

Use tools like OpenWrench to track completed PM visits, technician notes, and upcoming schedules. Make sure every visit includes a checklist of completed tasks and that the technician signs it.

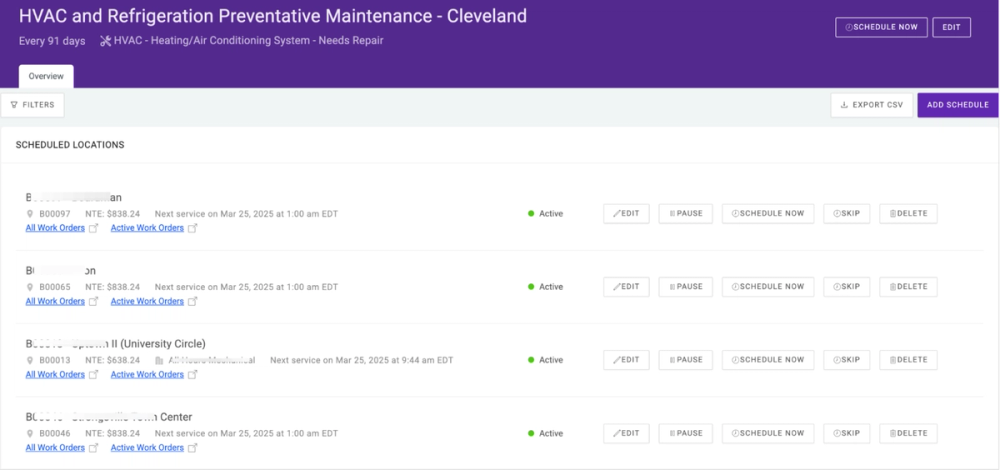

See preventative maintenance schedules for all your locations with OpenWrench. You can quickly edit, pause, skip, or move up PM visits in one place. Plus, all previous and active work orders are linked to each location for easy access.

2. Train Staff to Perform Basic Checks and Regular Cleaning

Your staff plays a vital role in keeping refrigeration systems running smoothly between regular maintenance services. Equipping them with basic inspection and cleaning skills allows you to catch small problems early and avoid costly emergency service calls.

“When PM companies aren’t there, it falls on the restaurant to clean and do routine maintenance,” says Danny. “It’s like having a maid who comes to your home once a month. That’s not the only time it gets cleaned. It has to be done in between too.”

Every week, your location staff should:

- Monitor temperatures at least once a day, first thing in the morning and at scheduled times throughout the day

- Check for leaks and water puddles under or around units

- Listen for unusual noises, like grinding or humming sounds, from compressors or fans

- Clean condenser coils, door seals, fans, and vents

- Look for cracks or tears in door gaskets

- Wipe down interior and exterior surfaces

- Check for frost buildup

To help your staff succeed, develop an easy-to-follow guide for daily, weekly, and monthly checks. Include tasks like temperature logs, gasket inspections, and coil cleaning reminders.

Platforms like OpenWrench make it simple to share these maintenance checklists across multiple locations, ensuring consistency. Staff can also quickly record their checks and report any issues they find.

Keep the instructions straightforward and prioritize tasks that anyone can do. “They just need to do simple things, like take the front screen off a refrigeration unit and check if it’s clean,” Danny explains.

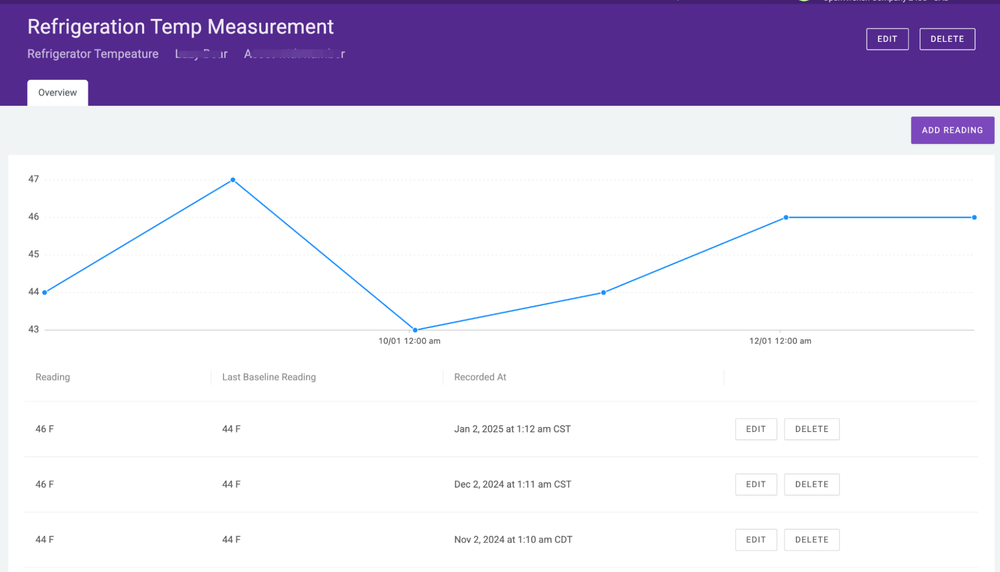

OpenWrench lets your location staff log daily refrigerator temperature checks right from their mobile device. This gives you access to refrigeration metrics across all locations so you can proactively monitor their performance and schedule service visits before they break down.

3. Avoid Overloading and Poor Placement

Proper placement and loading are critical for refrigeration performance. Blocking vents or placing units near heat sources, like fryers, reduces efficiency. Overloading, especially during busy times, can freeze up units.

“Coolers are built to accommodate what they have,” Danny explains, “but when you stack product to the ceiling, there’s no airflow.”

These mistakes often go unnoticed until they cause a failure during a critical time. Here’s how to optimize your equipment placement and loading:

- Conduct regular site surveys: Check that refrigeration units are positioned away from ovens, griddles, fryers, and other hot equipment and have enough space around them for proper airflow.

- Designate loading zones: Mark areas inside walk-ins where products should and shouldn’t be stored to avoid overcrowding key airflow zones.

- Consider climate control: Keep units in well-ventilated, temperature-controlled areas. Avoid placing units in spaces prone to high humidity or temperature spikes, which can strain the cooling system.

4. Prioritize Critical Equipment

Not all refrigeration systems impact operations equally. While losing a stand-up freezer isn’t catastrophic, downtime for a walk-in cooler can halt service.

Walk-in coolers, prep table refrigeration, and line equipment are often essential for daily operations. Losing one of these units can lead to food spoilage, lost revenue, and unhappy customers, so they need to be a top priority when failures occur.

Below are our tips for protecting your most critical refrigeration equipment:

- Create a response hierarchy: Rank your refrigeration units by how essential they are to operations. Units tied to food storage and preparation should be at the top of the list, while less-used equipment (like secondary freezers) can wait longer for repairs.

- Conduct regular risk assessments: Identify which units are most likely to fail based on age, condition, and usage. Focus your PM on these systems to reduce the chances of downtime.

- Establish rapid repair protocols: Partner with trusted vendors and negotiate service agreements that prioritize these units during emergencies.

5. Proactively Manage Warranty and Repair Costs

“If the restaurant manager doesn’t tell their vendor a piece of equipment is or might be under warranty, it often gets missed,” says Danny. “Then the restaurant loses money because they’re paying to fix a problem when it’s still under warranty.”

Here’s how to manage your warranties effectively:

- Digitize your warranty records: Store warranty details in a centralized digital system, such as OpenWrench, so they’re easy to access during service calls. Include purchase dates, coverage terms, and serial numbers for each piece of equipment.

- Train staff to flag warranty repairs: Teach managers and staff to always check for warranty coverage before authorizing repairs. A simple reminder can save significant costs.

- Track repair histories: Maintain detailed service records for each unit, noting what was repaired, when, and by whom. This helps determine whether the issue is warranty-eligible or recurring.

Not sure whether your equipment is still under warranty?

6. Build a Reliable Vendor Network

Working with the right service providers reduces downtime, ensures quality repairs, and keeps your equipment in peak condition. But not all vendors are created equal, and finding the right fit for your needs requires careful vetting.

“When you’re getting ready to pick a company, ask them how many cold-side techs they have,” Danny advises. “Because every tech may only be versed in hot side, cold side, or HVAC. Or a vendor might have 20 techs total but only five cold-side techs.”

Below are our best practices for building your vendor network:

- Ask for references: When comparing vendors, always ask them for a list of restaurant companies they’re working with, then call those facilities managers. This will help you discover potential issues before you work with them.

- Check performance and responsiveness: Choose vendors with a proven track record of reliability and timely service. Test their responsiveness during the vetting process by noting how quickly they answer questions or provide estimates.

- Leverage technology to manage vendors: Use platforms like OpenWrench to track vendor schedules, monitor performance, and consolidate invoices. A centralized system helps ensure you’re consistently working with the best providers across all locations.

7. Plan for Critical Failures

No matter how well you maintain your commercial refrigeration systems, they will still fail unexpectedly. But not all failures have the same impact.

While some units can wait for repair, others, like walk-ins or prep table coolers, are essential for daily service. Preparing ahead of time helps you avoid panicked decisions and costly repairs.

Danny recalls a restaurant with daily deliveries in anticipation of higher volume during the Daytona 500. Food was stacked to the ceiling in the walk-in, blocking airflow and making the unit freeze up. The freezer’s door heater was also broken, which caused frost buildup that made the door nearly impossible to open.

The solution came too late: renting an additional freezer unit. “The next year, we planned ahead,” Danny says. “We got a rental freezer and put it in the parking lot to handle the overflow.”

Here’s how you can plan for equipment failures:

- Map critical vs. non-critical equipment: In your contingency plans, prioritize systems essential to your daily operations, like walk-ins and prep tables.

- Identify temporary solutions: For critical equipment, explore backup options like portable refrigeration units or storing items at a nearby location, before emergencies happen.

- Document backup protocols: Create detailed plans for each critical system, including who to contact, where to source temporary equipment, and step-by-step instructions for minimizing downtime.

“If you’re prepared, you don’t panic,” Danny emphasizes. “That’s how you keep things moving even when something goes wrong.”

8. Use Software for Maintenance Tracking

Facilities management software helps streamline the process so everything is organized and no maintenance tasks fall through the cracks.

“If PM is done correctly, I will get notes for anything that needs to be repaired,” explains Danny. “If two days after a PM visit the equipment is down, I may call the service company and say, ‘PM was just done on Monday, and everything was fine. You sure you didn’t miss something?’”

A computerized maintenance management system (CMMS) makes tracking these notes easy so you can hold vendors accountable and ensure no detail gets missed. Here’s how to use this software to simplify your refrigeration maintenance:

- Report and track issues: Use software to document problems as soon as they occur. This creates a record for reference and ensures issues are addressed promptly.

- Approve and track work orders: With platforms like OpenWrench, you can view, approve, and track work orders across all your locations to monitor vendor performance and repair timelines.

- Receive PM alerts: Set automated reminders for upcoming PM visits to ensure critical tasks like coil cleaning or temperature checks aren’t overlooked.

- Analyze maintenance data: Review historical data to identify patterns, such as recurring issues with specific equipment or vendors. This helps prioritize repairs and make smarter budgeting decisions.

Simplify Commercial Refrigeration Maintenance with OpenWrench

TL;DR: Proper refrigeration maintenance is key to reducing downtime, cutting costs, and keeping your restaurant running smoothly. By combining preventative care, staff training, and smart planning, you can avoid costly breakdowns and extend the life of your equipment.

Here’s how OpenWrench can help you maintain commercial refrigeration equipment at your restaurants:

- Centralize maintenance tracking: Keep all your PM schedules, repair histories, and vendor information in one easy-to-access platform.

- Automate PM reminders: Stay on schedule with automated alerts for upcoming maintenance tasks, like coil cleaning or gasket inspections.

- Streamline vendor management: Track vendor performance, coordinate service calls, and consolidate invoices to simplify operations across multiple locations.