How to Reduce Restaurant Maintenance Costs and Avoid Costly RepairsNathalie Schrans

Nathalie Schrans

Nathalie Schrans

- 1. Do Regular Equipment Checks

- 2. Build Strong Vendor Partnerships

- 3. Maintain Preventative Maintenance (PM) Contracts

- 4. Train Staff on Equipment Care

- 5. Use Data to Make Informed Financial Decisions

- 6. Leverage Technology for Maintenance Management

- 7. Plan for Long-Term ROI

- Take Control of Your Restaurant Maintenance Costs with OpenWrench

In This Post

Picture this: It’s Friday dinner rush, and your kitchen hood ventilation system fails. Smoke fills the kitchen, staff are coughing, customers are complaining, and you’re left with an emergency repair bill that wrecks your budget.

We’ve all lived through these nightmare scenarios. That pit in your stomach when critical equipment fails at the worst possible moment, forcing you to turn away customers while staring down an emergency repair bill that will demolish your monthly maintenance budget.

We talked to Danny Koontz of Windy City Equipment, who has decades of experience in both restaurant facilities management and equipment repair, to get an inside look at reducing restaurant maintenance costs and finding trusted repair service vendors.

Whether you oversee five locations or 500, this guide will help you:

- Catch small issues before they become budget-busting emergencies

- Build a reliable vendor network that has your back when you need them most

- Make smarter decisions about repairs vs. replacements

- Create maintenance processes that your whole team will actually follow

Now, let’s dive into these tactics in detail to see how they’ll work for your restaurants.

1. Do Regular Equipment Checks

Your equipment checks don’t need to be complex hour-long inspections. The key is focusing on a few critical items that could shut down your operation if they fail.

Here are the main things you should check at least once a week:

- Refrigeration temperatures: Check temperature displays first thing in the morning and at scheduled times during the day. Listen for unusual sounds that could indicate the start of a problem.

- AC performance: Check that filters are clean and unobstructed and air is flowing strongly from all vents.

- Ice machine production: Open the bin first thing in the morning; if it's not full after overnight production, something’s wrong.

- Water heater temperature: Test hot water temperature at handwashing sinks and note if the water isn’t as hot as usual.

- Hot-side equipment (like ovens, fryers, and griddles): Pay close attention to cold spots that could indicate problems.

“I had a client who noticed their dining room was getting slightly warmer than usual. Instead of waiting for complaints, they called us immediately,” shares Danny. “Turns out their AC filters were getting clogged. A $100 preventive maintenance visit saved them from a much costlier emergency repair during weekend service.”

Document these checks somewhere that all onsite managers can access by:

- Creating simple checklists that focus on the most critical equipment

- Making it easy for staff to report issues immediately when they spot them

- Having a central place to track all maintenance history

- Setting up clear escalation procedures for when issues are found

OpenWrench makes this process seamless with mobile-friendly checklists and instant issue reporting that basic spreadsheets can’t match.

Pro tip: Always verify that non-working equipment is plugged in before calling a vendor. You’d be surprised how often this is the fix!

2. Build Strong Vendor Partnerships

“Too many restaurants want to work with a service provider but then drop them if something goes wrong,” says Danny. “Eventually you’ll have burned through all the service companies in your area. Every company will eventually make a mistake. That’s just human.”

Constantly switching vendors to save a few dollars can backfire, leaving you with unreliable service when you need it most. But strong partnerships lead to:

- Priority service during peak times and emergencies

- Proactive maintenance recommendations

- Honest advice on repair vs. replace decisions

Lasting vendor partnerships start with trust and honesty. Look for vendors who:

- Don’t promise what they can’t deliver

- Understand warranty coverage and communicate their limitations upfront

- Admit their mistakes and work to fix them

You and your vendors should also set clear expectations so you both understand what you’re getting into. This includes:

- Setting non-negotiable standards upfront, like warranty work procedures or repair status updates

- Defining realistic response times for different equipment

- Establishing transparent pricing and approval processes

“Stand up for your vendors in your own company when they’re right,” Danny advises. “If you throw them under the bus, word spreads to other vendors. Remember: repair vendors are a small industry and they talk. Restaurants that change vendors all the time get a bad reputation, and then you can’t find quality vendors to help you.”

Want support in finding vendors you can trust and managing them effortlessly?

3. Maintain Preventative Maintenance (PM) Contracts

Cutting PM contracts might seem like an easy budget fix, but it often leads to costly emergency repairs, which always cost more. Preventative maintenance helps you avoid:

- Overtime fees for emergency repairs

- Expedited shipping costs for parts

- Equipment failures during peak service times

- Damage that could shorten your equipment lifespans

“Let’s say you cut that PM contract, don’t change AC filters for six months, and suddenly your filters are so clogged they’re killing air efficiency,” Danny explains. “Now your dining room is too hot or too cold, customers are complaining, and you’re paying premium rates for a service tech to do what a junior maintenance person could have handled during routine PM.”

Here’s what smart PM contracts should cover:

- Quarterly HVAC service including filter changes

- Quarterly or semi-annual cleaning and inspection of walk-in coolers and freezers

- Hood system maintenance and cleaning verification

- Equipment-specific maintenance based on manufacturer recommendations

- Documentation of all maintenance activities and findings

OpenWrench helps track PM schedules, document maintenance history, and manage contracts across multiple locations and vendors — making it easier to protect preventative maintenance contracts in your operation’s future.

Pro tip: “PM contracts are typically fulfilled by younger, less expensive techs who are in training after trade school,” says Danny. “Compare that to emergency calls where you’re paying top dollar for experienced technicians — and often paying them overtime rates.”

4. Train Staff on Equipment Care

“Too many kitchens end up with costly damage because no one showed them the right way to clean and maintain equipment,” Danny points out. “I’ve seen staff clean inside an oven with a water hose because they want it spotless. Sure, the inside looks great — but they’ve completely fried the control panel with water damage.”

Staff are your first line of defense against equipment failures — if they know what to watch for. Train them to recognize warning signs, such as:

- If refrigeration temperature spikes, check for issues before food spoils.

- Inconsistent water pressure or water pooling around equipment could mean plumbing issues.

- Grease traps filling faster than normal could indicate system blockages.

- Equipment taking longer than usual to heat up often signals maintenance needs.

Make sure everyone knows how to communicate issues across shifts too. “We worked with a restaurant where different shifts kept noticing a walk-in cooler making unusual sounds,” shares Danny. “But because no one documented it or told the next shift, it took weeks before anyone realized this was a daily occurrence. By then, they were looking at a major compressor repair that could have been prevented.”

Pro tip: Put sticky notes in the corners of your oven hoods to confirm overnight cleaning. If the notes are gone, you’ll know they were actually cleaned.

5. Use Data to Make Informed Financial Decisions

Sometimes short-term thinking leads to much bigger costs down the road. Smart maintenance decisions require full visibility of your costs so you can make choices for the long haul.

One of the first places to start is with your Not-to-Exceed (NTE) limits for repairs. Avoid setting blanket limits that could delay critical repairs. Here are some tips:

- Set higher limits for critical equipment like HVAC and refrigeration.

- Set lower limits for non-critical equipment.

- Factor in total service costs to avoid multiple visits.

- Adjust limits based on equipment age and value.

Another big decision you’ll face is whether to repair or replace equipment. “If a repair costs 50% of replacement cost, that’s usually your signal to think about replacing,” Danny advises. You should also consider:

- Equipment age and depreciation value

- Previous repair investments

- Energy efficiency of newer models

- Operational impact of downtime

OpenWrench helps track all these crucial data points in one place, making it easier to spot trends and make informed decisions about repairs, replacements, and maintenance investments.

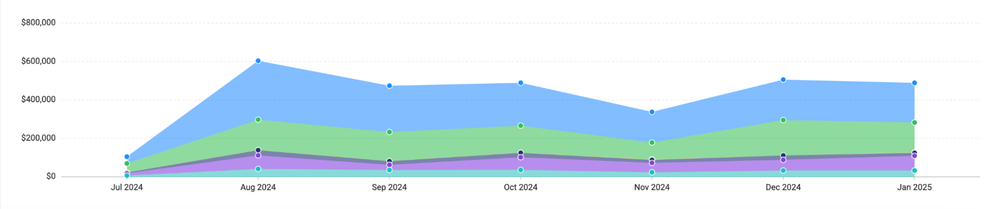

OpenWrench's maintenance trends feature helps you easily track each location's monthly spending on certain equipment. This helps you proactively adjust budgets and plan better for the next year.

6. Leverage Technology for Maintenance Management

Gone are the days of tracking maintenance with paper logs and sticky notes scattered across multiple locations.

But maintenance technology is only as good as the people using it. The best systems are the ones your team will actually use. Look for platforms that:

- Make it easy to report issues on the go

- Document equipment issues with photos and detailed notes for vendors

- Integrate with your existing workflows

- Offer clear, actionable data insights

- Scale as your operation grows

Instead of wondering if that walk-in cooler is really using more energy than last year, you can pull up the data and know for sure. Or rather than guessing if a vendor is meeting their response time commitments, you can track it automatically.

Here’s where platforms like OpenWrench shine — they bring all these capabilities together in one place with features like:

- Mobile-friendly issue reporting

- Automated maintenance scheduling

- Real-time vendor communication

- Equipment history and repair costs tracking

- Cost analysis and reporting

7. Plan for Long-Term ROI

Think of restaurant maintenance like maintaining your car: sure, you could skip oil changes to save money today, but you know that decision will cost you much more down the road.

Consider long-term investment strategies like:

- Upgrading to energy-efficient equipment for lower monthly utility costs and better performance and reliability

- Investing in preventative technology like temperature sensors, performance analytics, and early warning detection

- Focusing on equipment standardization to simplify maintenance, make parts inventory easier, and make repairs more efficient

- Building your maintenance data bank by tracking repair frequencies, documenting equipment lifecycles, and analyzing cost trends.

Let’s say a new high-efficiency refrigeration system might cost 30% more upfront, but it can slash your energy bills by up to 40% while requiring far fewer emergency repairs. Over a five-year period, that “expensive” upgrade could actually save you thousands of dollars per unit.

Take Control of Your Restaurant Maintenance Costs with OpenWrench

TL;DR: Start with what matters most for your operation. Maybe it’s getting your equipment checks dialed in or finding a reliable HVAC vendor. Pick one thing, get it working smoothly, then build from there. But don’t skip PM or constantly switch vendors to save a few bucks — it’ll only end up costing you way more in the long run.