How to Set Up a Preventative Maintenance Plan for Restaurant Kitchens + Free PM Checklist TemplateStacey Breyer

Stacey Breyer

Stacey Breyer

You’re juggling multiple restaurant sites when the calls start flooding in: a clogged grease trap, a failed HVAC system, and a broken oven — all in one weekend.

Sound familiar?

For restaurant facilities managers, this kind of chaos is all too common. However, the right preventative maintenance plan makes these challenges far more manageable and less frequent.

A standardized commercial kitchen maintenance checklist is the key to taking control. It simplifies preventative maintenance (PM) processes, ensures health and safety compliance, and prevents costly equipment downtime. Streamlined PM across all your restaurant locations will save time, cut expenses, and keep your kitchens running smoothly.

This guide covers our top tips for commercial kitchen maintenance and breaks down essential restaurant PM tasks. By the end, you’ll be able to:

- Implement a standardized maintenance checklist to reduce equipment downtime and improve efficiency

- Delegate tasks effectively between your team and trusted service providers

- Use our free downloadable commercial kitchen maintenance checklist at every location

- Stay compliant with health and safety regulations while preventing costly emergencies

Preventative maintenance doesn’t have to be overwhelming. With the right plan, you’ll feel confident and prepared to handle any challenge.

5 Tips for Commercial Kitchen Maintenance

Maintaining a commercial kitchen doesn’t have to be chaos. These actionable tips will help you streamline maintenance, prevent costly repairs, and keep your equipment running efficiently.

1. Document all maintenance tasks and inspections

A detailed log ensures accountability for completed tasks and helps you track trends that signal recurring equipment problems.

Documentation also provides essential evidence of compliance during health and safety inspections. And it empowers you to make data-driven decisions about repairs, replacements, and future planning.

Start by choosing a system that works best for your team. Digital tools like spreadsheets or maintenance management software like OpenWrench streamline the process. But even a physical logbook can work if used consistently.

For each task, record:

- The date and time the task was completed

- The person responsible for performing the maintenance or inspection

- The equipment and task details, including what was serviced or inspected

- Observations or follow-up needs, like parts that need replacing or potential issues to monitor

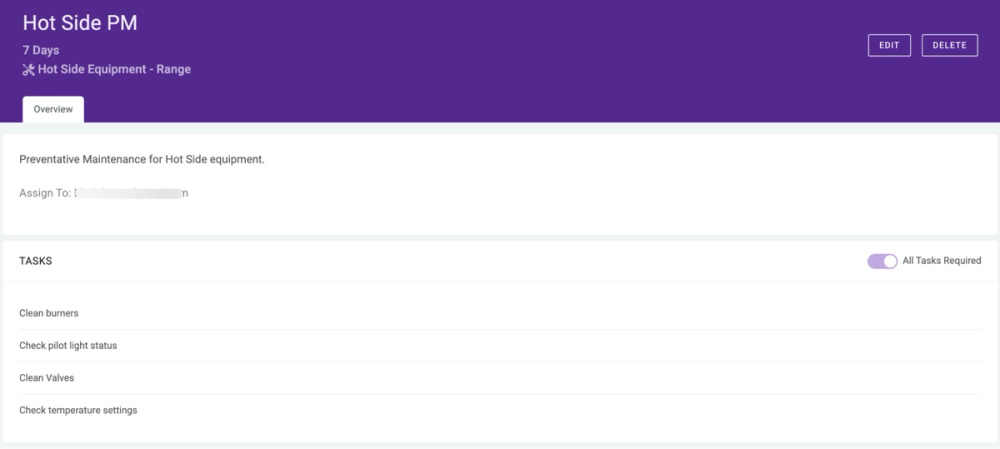

OpenWrench lets you document preventative maintenance tasks, track PM history, and even upload service reports directly from your mobile device. With all your data in one place, you’re always inspection-ready and better equipped to keep your kitchen running smoothly.

2. Store equipment warranty and service records

Imagine your commercial refrigerator stops cooling during peak hours. Instead of panicking, you quickly pull up the warranty, schedule a free manufacturer repair, and save thousands.

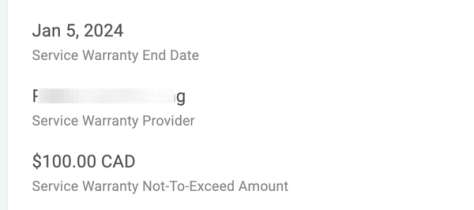

Warranties and service histories are your safety net for unexpected equipment issues, but they’re only helpful if you can find them. Keeping these records in one place lets you:

- Claim repairs quickly to avoid unnecessary expenses

- Track maintenance requirements to ensure equipment is serviced on time and extend its lifespan

- Decide on repair vs. replacement based on service history and financial data

Here’s how to stay organized:

- Digitize everything: Reduce clutter and make records accessible from anywhere by storing them digitally.

- Use labeled folders: Organize files by equipment type to find what you need quickly.

- Leverage cloud storage: This ensures you can retrieve records anytime, especially when remotely managing multiple locations.

OpenWrench takes the hassle out of recordkeeping. Our platform stores all equipment details, including warranties, service histories, and purchase dates. When an issue arises, you’ll have everything you need at your fingertips, saving you time and money.

With OpenWrench’s warranty and service records features, you can log all the essential details about your equipment so your location staff can access them whenever they need.

3. Train staff on proper equipment use and care

Improper equipment use is one of the quickest ways to rack up avoidable repair bills. Training prevents misuse, reduces wear and tear, and keeps operations running smoothly. It also promotes safety and reduces the risk of accidents that could injure employees and damage equipment.

Here’s how to implement training:

- Schedule monthly or quarterly training sessions: Teach staff how to operate, clean, and troubleshoot commercial kitchen equipment to ensure proper use and care.

- Incorporate equipment care into onboarding: Train new hires during onboarding to build good habits from day one.

- Provide instructional guides: Place clear, easy-to-follow guides near equipment for quick reference during daily operations.

OpenWrench links equipment care information directly to specific assets and tags them with QR code stickers. Your staff can easily identify kitchen equipment and quickly bring up guides, troubleshooting tips, and maintenance history on their mobile devices.

4. Partner with reliable service providers

You can’t handle every maintenance task in-house, and that’s okay. Partnering with experienced service providers ensures specialized tasks, like hood cleaning and HVAC servicing, are done right the first time. The result? Less downtime, fewer compliance issues, and more peace of mind.

A strong vendor relationship ensures timely service, reduces costly mistakes, and helps prevent emergencies. Here’s how to find and build these relationships:

- Research thoroughly: Look for local vendors with strong reviews, relevant certifications, and a track record of reliability. Ask restaurant colleagues for referrals too.

- Request quotes: Compare services and pricing to ensure you’re getting value without compromising quality.

- Establish recurring schedules: Partner with providers to set up regular maintenance for tasks like hood cleaning, grease trap emptying, and HVAC inspections.

- Communicate expectations clearly: Outline your needs, compliance requirements, and preferred timelines to avoid misunderstandings.

OpenWrench’s network of 10,000+ service providers makes it easy to find trusted vendors. Filter our WrenchHub network by geography and service type to source the exact partner you need. Or get tailored recommendations from our customer success team to find the right vendor for every task.

Ready to simplify your vendor management?

5. Use facilities management software to streamline scheduling and recordkeeping

Managing maintenance across multiple locations can feel overwhelming — Computerized Maintenance Management Systems (CMMS) like OpenWrench can transform your operations. The software simplifies scheduling, tracks equipment history, and ensures no task gets overlooked.

Here’s how to use a CMMS to make restaurant facilities management a breeze:

- Decide on your maintenance needs: Consider operational tasks (like calibrating equipment or cleaning grease traps) and process challenges (like scheduling routine maintenance or managing multiple locations).

- Research your CMMS options: Look for features like task automation to avoid missing PM tasks and vendor management to streamline service appointments and communication.

- Set up equipment profiles: Add details like make, model, purchase date, and maintenance history for every critical asset.

- Input maintenance schedules: Schedule recurring tasks, such as monthly deep fryer maintenance, to ensure consistency across all sites.

- Train your team: Show staff how to use the system effectively, from logging tasks to accessing maintenance records.

OpenWrench goes beyond standard CMMS capabilities. Our intuitive platform lets you manage schedules, track maintenance histories, and receive real-time updates across all your locations. With features like automated reminders and centralized data storage, you’ll never miss a critical task again.

The Essential Commercial Kitchen Maintenance Checklist

We created a comprehensive commercial kitchen maintenance checklist to help you streamline your maintenance tasks across locations. Following a standardized checklist will ensure consistency across locations and avoid costly surprises.

Daily maintenance tasks

- Sanitize food preparation tools: Clean slicers, mixers, and prep equipment after each use to maintain hygiene and prevent cross-contamination.

- Clean cooking equipment: Wipe down ovens, griddles, and fryers daily to remove grease and food debris.

- Disinfect surfaces: Sanitize countertops, cutting boards, and utensils after use to meet food safety standards.

- Sweep and mop floors: Clear spills and debris to reduce slip hazards and maintain cleanliness.

- Check refrigerators: Ensure consistent temperatures and clean up spills or disorganized contents.

- Empty trash cans: Remove trash daily and clean receptacles to prevent odors and pests.

Whether it’s a clogged drain or fluctuating refrigerator temperatures, your staff can use OpenWrench’s mobile-friendly app to report problems instantly. Real-time updates and notifications ensure facilities managers stay informed and can act quickly to resolve issues.

See our mobile-friendly issue reporting and tracking features in action

Weekly maintenance tasks

- Clean grease filters: Remove and clean exhaust system filters to prevent buildup and maintain airflow.

- Deep clean equipment: Scrub ovens, grills, and fryers to remove baked-on grease and debris.

- Check ice machines: Monitor performance for low output or unusual noises. Sanitize interiors to prevent bacterial growth.

- Test handwashing stations: Ensure all handwashing stations have adequate soap, paper towels, and consistent water pressure.

- Lubricate and tighten small equipment: Perform basic maintenance on movable parts of tools like mixers, slicers, and blenders to prevent wear and tear.

- Organize storage: Rearrange stockroom shelves, removing expired or damaged items.

- Inspect pest control measures: Check traps and bait stations, replacing or cleaning as needed. Escalate persistent issues to a pest control provider.

- Inspect exhaust fans: Check exhaust fans weekly for proper operation, unusual noises, or visible grease buildup. If issues continue, schedule a vendor.

Monthly maintenance tasks

In this section and the following ones, we’ll split tasks into two groups:

- Internal tasks can be handled by kitchen staff without specialized expertise, but proper training is recommended for consistency and safety.

- Vendor tasks require professional service providers to perform specialized maintenance to ensure compliance and efficiency.

Internal PM tasks

- Clean air vents and replace filters: Remove dust and replace filters to maintain HVAC efficiency.

- Check door seals: Inspect refrigerator and freezer seals and gaskets for cracks or wear and clean them to prevent air leaks.

- Inspect for plumbing leaks: Look for visible leaks or drainage issues and report persistent problems.

- Replace water filtration system filters: Follow the manufacturer’s guidelines to maintain clean water for kitchen use.

- Test emergency lighting: Ensure lights are operational in all critical areas.

Vendor PM tasks

- Clean grease traps and hydro jet sewer lines: Use a licensed grease trap cleaning service to remove accumulated grease and schedule hydro jetting for connected sewer lines, especially in colder months. This will reduce the risk of sewer backups caused by clogs inside and outside the traps.

- Service refrigeration coils: Hire a technician to clean condenser coils and maintain cooling efficiency.

- Inspect fire suppression systems: Partner with a fire safety specialist to test and verify that the Ansul system or equivalent fire suppression system works and meets safety standards.

- Inspect and service backup power systems: Hire a technician to check the readiness of generators or other backup power systems.

Quarterly maintenance tasks

Internal PM tasks

- Calibrate equipment: Test and adjust thermometers, ovens, and fryers for accuracy.

- Clean storage areas: Remove items, sanitize cold storage shelves, and reorganize the contents.

- Clean light fixtures and replace bulbs: Clean dust and grease from light fixtures and replace any burnt-out bulbs in both kitchen and dining areas.

- Test equipment alarms: Ensure all alarms (e.g., for temperature fluctuations or fire suppression systems) function correctly.

- Conduct safety training: Refresh staff on fire protocols, equipment use, and emergency responses.

Vendor PM tasks

- Clean hoods, ducts, and fans: Schedule a professional to remove grease buildup and avoid fire risks.

- Jet or snake sewer lines: Partner with a plumbing vendor to prevent clogs and backups.

- Inspect structural elements: Hire a contractor to check for leaks, cracks, or damage in walls and ceilings.

Semi-annual maintenance tasks

Internal PM tasks

- Inspect kitchen floor grout: Deep clean tiles and check for cracks or damage.

- Check exhaust fan belts: Clean and ensure they are free of cracks and wear. Replace belts if signs of deterioration appear.

- Check fire suppression nozzles and links: Train staff to visually inspect the fire suppression system for any visible blockages, misalignments, or wear on nozzles and links. Escalate concerns to a fire safety specialist for further action.

Vendor PM tasks

- Reseal tiles: Hire a floor maintenance professional to reseal tiles after grout cleaning.

- Perform deep equipment servicing: Hire licensed technicians to service refrigerators, freezers, and HVAC systems. This includes checking and repairing seals, hinges, and electrical components for optimal efficiency.

- Perform pest control: Schedule a comprehensive pest inspection and treatment that covers preventative measures and active infestations.

Annual maintenance tasks

Internal PM tasks

- Review documentation: Collect maintenance logs and ensure all records are audit-ready.

- Inspect for major repairs: Walk through and identify items needing major repairs or replacements, like the walk-in freezer’s cracked door seal or a loose oven door. Flag any issues that require professional evaluation.

Vendor PM tasks

- Conduct a comprehensive fire safety system inspection: Partner with a licensed fire safety professional to ensure fire suppression systems comply with safety regulations. Inspect, refill, or replace fire extinguishers throughout the kitchen and dining areas.

- Perform a health and safety audit: Hire a certified inspector to evaluate compliance with local health and safety codes and identify areas for improvement or updates.

- Schedule major repairs and upgrades: Work with equipment repair specialists or suppliers to replace outdated or heavily worn kitchen equipment.

- Inspect insulation on refrigeration lines: Partner with a technician to ensure refrigeration line insulation is intact and replace any worn areas to prevent energy inefficiencies.

- Evaluate energy efficiency: Work with a technician to assess your energy usage and recommend replacements or improvements to reduce utility costs and environmental impact.

OpenWrench’s spend tracking tools let you set annual budgets for maintenance tasks, track expenses in real time, and enforce approval rules to prevent overspending for complete control over repair and kitchen equipment maintenance costs.

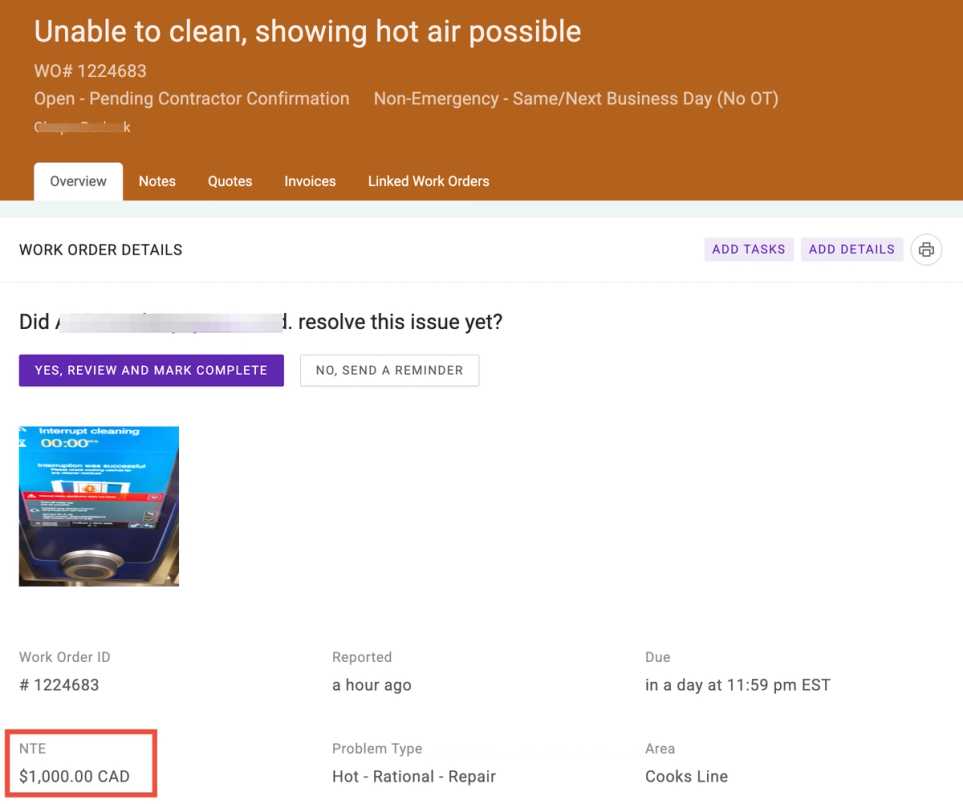

OpenWrench makes it easy to set Not-to-Exceed (NTE) limits for all equipment so you can avoid overspending. You can edit this directly in the work order or set NTEs for overall equipment categories like HVAC or refrigeration.

Free Downloadable Preventative Maintenance Template

Download our free preventative maintenance template so you don’t have to build one from scratch. You can print it out and pin it to your office wall or download it and save it on the cloud so any location’s team can access it.

Try our restaurant PM checklist template

Take Control of Commercial Kitchen Maintenance with OpenWrench

TL;DR: Preventative maintenance simplifies processes, reduces emergencies, and ensures your kitchen operations stay efficient and compliant, no matter how many locations you manage. Our PM checklist template will make implementing and standardizing these processes easier.

Here’s how OpenWrench can help:

- Streamline equipment maintenance across locations: Our tools keep all your PM schedules and records in one central area so nothing gets missed or forgotten.

- Simplify vendor management: Connect with trusted service providers and easily schedule their maintenance tasks to reduce equipment downtime.

- Stay compliant: Track equipment history and service records to meet health and safety regulations.