The Ultimate Guide to Commercial Plumbing Maintenance for RestaurantsMatt Velker

Matt Velker

Matt Velker

- 1. Create a Standardized Plumbing Emergency Response Plan

- 2. Build Strong Vendor Relationships

- 3. Use a Computerized Maintenance Management System (CMMS)

- 4. Prioritize Regular Drain Maintenance

- 5. Make Sure Grease Traps Are Properly Cleaned

- 6. Track Water Heater Performance

- 7. Identify and Prevent Hidden Plumbing Failures

- Stay on Top of Commercial Plumbing Maintenance with OpenWrench

In This Post

Plumbing problems are one of the biggest headaches in restaurant maintenance. But most of these issues, like clogged drains, grease trap backups, and busted water heaters, are totally preventable. A proactive plumbing maintenance plan can help facilities managers avoid costly emergency repairs, reduce downtime, and keep operations running smoothly.

We spoke with Danny Koontz of Windy City Equipment, a seasoned restaurant facilities management expert, to get expert insights on managing restaurant plumbing across multiple locations. In this guide, he shares real-world strategies for preventing plumbing failures, improving vendor relationships, and ensuring consistent maintenance at every restaurant location.

Here’s what you’ll learn:

- How to create a standardized emergency response plan so staff can act quickly when plumbing issues arise

- Why strong vendor relationships lead to faster service and fewer repair headaches

- Best practices for drain and grease trap maintenance to avoid backups and costly downtime

- Warning signs of hidden plumbing failures and how to catch them before they become disasters

1. Create a Standardized Plumbing Emergency Response Plan

Plumbing emergencies always seem to happen at the worst possible time — during dinner rush, on a weekend, or late at night when no one is around to catch the problem early. Without a plan, every minute wasted figuring out what to do makes the situation worse.

“The difference between a minor disruption and a full-blown crisis often comes down to response time,” Danny says. “Your first call for a grease trap issue is different from a severe water leak. If you don’t have this figured out ahead of time, you’ll waste precious time when things go wrong.”

To avoid chaos, every location should have a clear emergency plan:

- Document the process: Outline step-by-step instructions for handling plumbing failures. Post this plan in every manager’s office and store it digitally.

- Know shutoff points: Every manager should know where the main water shutoff valve is, plus any localized shutoffs for dishwashers, sinks, and ice machines. Include this in onboarding, routine training, and all maintenance checklists.

- Run emergency drills: Just like fire drills, practice plumbing emergency scenarios once a quarter so staff don’t have to figure things out for the first time when disaster strikes.

If a pipe bursts in the dish area during dinner service, the difference between closing for the night and keeping your daily operations running comes down to whether the staff knows what to do.

2. Build Strong Vendor Relationships

During a plumbing emergency, restaurants with pre-established vendor relationships get priority service. Those without them scramble for help — often at a premium cost.

Some facilities managers make the mistake of switching vendors too often, thinking they’ll save money. “Your vendors are your partners,” Danny says. “If something goes wrong, work with them to fix it. If you burn through vendors too quickly, you’ll run out of options.”

Instead of chasing the lowest price, focus on vendors who prioritize your business. Here’s how to build lasting vendor relationships:

- Vet and onboard preferred plumbing vendors: Don’t just pick the first company you find. Look for vendors with solid reviews, experience in restaurant plumbing, and clear service-level agreements (SLAs).

- Negotiate response-time guarantees: When a drain backs up mid-shift, you don’t have time to wait 48 hours for service. “Ask vendors to commit to a response time,” Danny says. “Is it four hours? Six? Don’t just assume they’ll show up right away when you need them.”

- Centralize vendor contacts and maintenance history: Track service records, contract details, and past performance in one place to ensure consistency across locations.

Strong vendor relationships are built on trust, reliability, and consistency across all locations. To maintain these relationships, you need a system to track performance and ensure high-quality service. When vendors know they’re being evaluated consistently, they’re more likely to prioritize your business and respond faster.

Vendor management is just one part of running an efficient restaurant facilities program. For a full breakdown of best practices, check out our Restaurant Facilities Management 101 guide for a full breakdown of best practices.

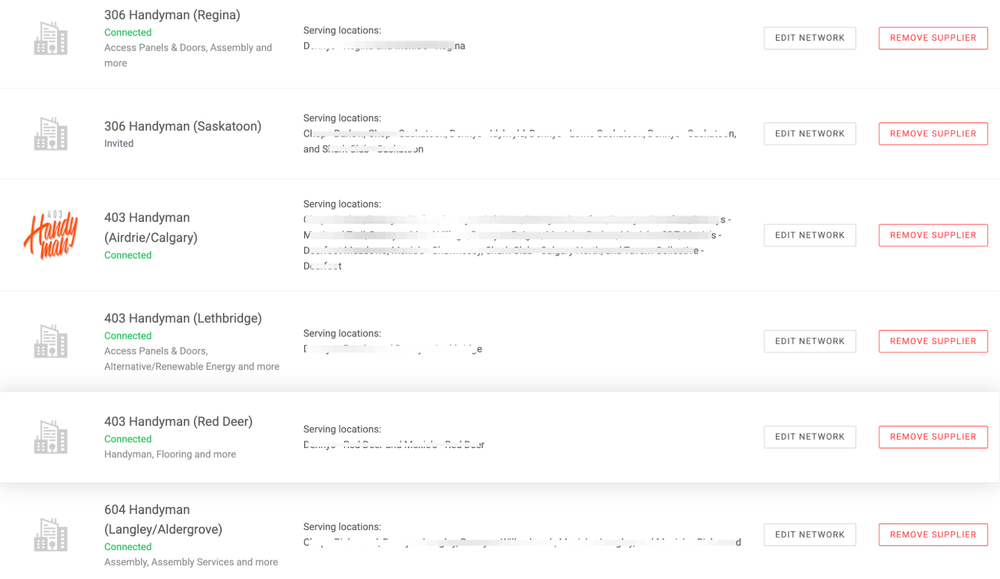

Get a complete view of your entire vendor network with OpenWrench's user-friendly vendor management feature. Service providers can easily connect to OpenWrench so you can communicate with them, track work orders, and manage invoices all in one place.

3. Use a Computerized Maintenance Management System (CMMS)

“You need a record of what’s happening at every location,” Danny says. “Otherwise, you’re going to pay for the same repairs over and over.”

Plumbing problems tend to slip through the cracks when they aren’t documented properly. Without a record of past issues and repairs, the same problems can keep happening — like a recurring drain backup that gets temporarily cleared instead of fully fixed.

A maintenance tracking system helps you stay ahead of frequent issues and avoid unnecessary costs. Here’s how to make it work:

- Use a CMMS to track service requests and work orders: A computerized maintenance management system (CMMS) keeps a digital record of every plumbing issue, vendor response, and repair history, so nothing gets missed.

- Require location managers to log plumbing issues: You need to know if a store reports the same clogged drain every few weeks. It could mean there’s a larger underlying issue that a quick fix won’t solve. A CMMS makes it easy to spot patterns instead of treating each issue as a one-off.

- Set automated reminders for recurring maintenance tasks: Preventative maintenance, like drain cleanings and grease trap pump-outs, should be scheduled before problems arise.

A disorganized maintenance process leads to repeat plumbing failures, costly repairs, and unnecessary downtime. With a CMMS like OpenWrench, you can easilytrack plumbing issues and store maintenance history across all locations.

4. Prioritize Regular Drain Maintenance

According to Danny, drain backups are one of the most common and avoidable plumbing issues he sees in restaurants. The problem? Drains are ignored until something overflows, and by then, it’s too late.

A clogged drain can shut down a dish pit, slow kitchen operations, or, worst case, flood the floors and force a full-service stop. Here’s how to prevent backups before they happen:

- Install lockable drain covers: Staff removing drain covers to hose down food scraps is a recipe for disaster. A locked cover keeps utensils, food, and other debris from the pipes.

- Require daily dry sweeping before mopping: Mopping pushes food scraps into drains. A simple dry sweep before wet cleaning helps prevent unnecessary buildup.

- Schedule quarterly hydro-jetting for high-traffic kitchens: Even with regular maintenance, some buildup is inevitable. A scheduled deep clean ensures drains stay clear before problems arise.

Make drain maintenance part of your preventative maintenance plan to avoid costly plumbing failures.

“One of our plumbers found five forks, three knives, and two spoons in the drain. I’ve even found a shoe and a wig in a drain once,” says Danny. “So how did that happen? Someone pulled the drain cover off and hosed everything down. That’s preventable.”

Ready to put your maintenance on autopilot?

5. Make Sure Grease Traps Are Properly Cleaned

Many facilities managers assume that if a vendor comes out to clean the grease trap, the job is done right — but that’s not always the case. Some vendors skim grease traps instead of fully pumping them, which leaves behind built-up grease that quickly clogs the system again.

Danny has seen it happen too many times. “If a vendor is offering to clean your grease trap for way cheaper than everyone else, they’re probably just skimming it. It only takes one major backup to wipe out all the ‘savings’ you thought you had.”

Here’s how to ensure your grease traps are properly maintained:

- Train managers to check grease trap cleaning quality: Traps should be fully pumped and cleared, not just skimmed. If a vendor leaves behind a thick layer of grease, the job isn’t done right.

- Schedule routine grease trap cleanings: The frequency depends on volume, but most restaurants need cleanings every 30 to 90 days to prevent buildup.

- Log all service records: Keep track of cleaning dates and vendor details to ensure traps are maintained on schedule and to catch recurring issues before they turn into bigger problems.

“Ask yourself if your team even knows where their grease traps are,” Danny says. “A lot of managers don’t. It’s usually in the parking lot, underground. If your team doesn’t know where it is, they aren’t checking it.” A simple training session can prevent the last-minute scramble of locating the trap when it’s time for maintenance.

Grease trap failures can lead to major plumbing issues and even health code violations. Check out our health inspection preparation guide to see why regular plumbing maintenance helps you stay compliant.

6. Track Water Heater Performance

“Nothing will shut a restaurant down faster than a broken water heater,” Danny says. “No hot water, no service.” Without hot water, there is no dishwashing, no handwashing, and no way to stay compliant with health codes.

The problem is that water heaters are often hidden away in storage rooms or utility closets, forgotten until something goes wrong, like a leak from a rusted pipe. Here’s how to stay ahead of water heater failures:

- Check water temperature consistency weekly: Sudden temperature drops can signal a failing heating element, sediment buildup, or other mechanical issues.

- Drain and flush water heaters annually: Over time, sediment collects at the bottom of the tank, reducing efficiency and increasing the risk of failure. A yearly flush helps extend the unit’s lifespan.

- Log maintenance records to track unit lifespan: Keeping track of installation dates, past repairs, and service history makes it easier to decide when a replacement is necessary instead of waiting for a failure.

Water heater maintenance is just as important as refrigeration upkeep when it comes to preventing operational disruptions. Check out our commercial refrigeration maintenance guide for more ways to track and maintain critical equipment.

7. Identify and Prevent Hidden Plumbing Failures

Not all plumbing problems are obvious. Some start small — a slow drain here, a faint sewage smell there — but if left unchecked, they can lead to major structural damage and costly repairs.

The trick is catching these hidden issues before they escalate. “A weird smell in a restaurant is usually a bad sign,” says Danny. “If it doesn’t go away, figure it out fast before customers start noticing.”

Here’s how to detect hidden plumbing issues before they become disasters:

- Require shift managers to complete daily restroom inspections: They should look for active leaks under sinks, check for low water pressure, and make sure drains are flowing properly.

- Make sure restrooms are stocked with the right supplies to prevent plumbing issues: Keep an eye on supply levels and ensure trash bins are available and emptied regularly to prevent guests from tossing waste into toilets.

- Use smoke testing to detect plumbing vent leaks: If smoke escapes through unexpected areas, it means there’s a break in the drain-waste-vent (DWV) system allowing sewer gases to seep into the building. A damaged or clogged vent can cause slow drains, foul odors, or even gas buildup inside the restaurant.

- Conduct annual camera inspections of underground pipes: This helps spot cracks, blockages, or buildup before they cause backups or leaks.

Imagine a shift manager notices a small leak under the restroom sink but assumes it’s not urgent. Over time, that slow drip weakens the pipes, causing a full break that floods the stall right before a busy lunch rush.

Now, instead of a quick fix, the restroom is out of order, and you’re dealing with a major repair, unhappy customers, and potential health hazards.

Stay on Top of Commercial Plumbing Maintenance with OpenWrench

TL;DR: Plumbing failures are costly, disruptive, and largely preventable. The key is staying ahead of issues with proactive maintenance, strong vendor relationships, and a centralized tracking system.

OpenWrench helps facilities managers stay on top of plumbing maintenance with:

- Issue tracking: Log plumbing problems as they happen and monitor recurring issues.

- Automated maintenance scheduling: Set reminders for routine drain cleanings, grease trap pump-outs, and water heater inspections.

- Vendor management: Store contact information, track service history, and ensure vendors meet response-time commitments.